Apr 20, 2022

Is 3D Printing really "green manufacturing"?

With each passing day, it becomes clearer that direct action to prevent climate change is necessary. As a business based in Miami, FL we are intimately aware of the regular effect sea level rise has on our city and the amount of garbage that washes up on our beautiful beaches. One of the calls from the advanced manufacturing industry is to embrace 3D printing, and its opportunity to reduce waste, so we wanted to take a look and see where the industry is headed. The answer is…. you’ll have to wait, no spoilers here!

Let’s look at this through the lens of the 3 R’s: Reduce, Reuse, and Recycle.

Reduce

Wendell Berry, famed environmentalist, once wrote “Do unto those downstream as you would have those upstream do unto you.”

We’ve spent some quality time this year discussing the opportunity advanced manufacturing brings to your supply chain. This is where some of the rubber hits the literal road. Fast Company put together a great piece this year about where you can tweak your supply chain to make your business more earth friendly. The gist is to categorize a business’ emissions responsibility in terms of “scopes”.

- Scope 1 refers to the emissions from sources that a business directly owns or controls, like on-site boilers, furnaces or a fleet of delivery vehicles.

- Scope 2 refers to emissions associated with energy the business purchases from the grid.

- Scope 3 involves all other emissions up and down the supply chain, both upstream suppliers and downstream customers.

You can positively affect scopes 1 and 3 by near-shoring and re-shoring your supply chain or bringing it in-house. Then you will not have to worry about the next time the Suez Canal suffers a traffic jam, or if the first printing of your cookbooks are on one of the thousands of containers that just fall into the ocean each year.

In a thorough review of 3D Printing technologies done in March 2020, AMFG.AI, determined that industrial 3D printing is more sustainable than its subtractive counterparts. This feels like common sense, when 50-90% of the material can be lost in CNC fabrication. And unlike the shredding and melting of plastic, the smelting of metal is far more difficult process to undertake in-house, let alone on your workbench. Other factors they considered when rendering a decision was how the design process could consolidate part assemblies or lighten the piece while maintaining structural integrity, leading to additional engineering benefits.

Reuse

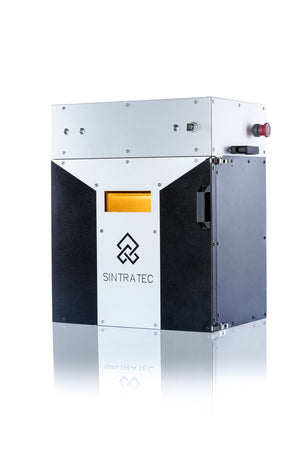

Focusing on one of the technologies we use and distribute at 3DChimera, Selective Laser Sintering (SLS), there are a couple ways that your 3D printing, regardless of scale, can achieve a more positive eco-impact.

For the Sintratec SLS machines, any powder that is not sintered during the printing process, can be filtered and reused at approximately 99%! Which is tremendously economical when you see how much powder fills the build tray.

To that end, there are guidelines for reuse, in the desktop Kits, you need to mix Nylon PA12 with 70% virgin powder to 30% used powder. In their larger, modular model, the S2, Sintratec was able to flip the formula around and you can include up to 70% reclaimed powder in every print run.

For their flexible TPE it’s an even 50/50 split on both machines.

Recycle

It’s likely that right now, in your home or business, you have access to a recycling bin for paper, plastic, glass and/or metal. As of 2018, the Environmental Protection Agency reported that paper makes up 66.5%, metals are 12.6%, glass and plastic both at 4.4%, which is significantly lower that the generally reported statistics that plastic is recycled at a rate of 9% annually. That’s a dismal recapture of a resource that the majority of 3D printing users require.

Based on the products above that let you easily reuse SLS powder, let’s see what’s how three different organizations are tackling recycling…

Be the shredder you want to see in the world

When it comes to recycling or recycled filament, the industry is still pretty nascent, mostly due to the complex chemistry of plastic. Petrochemicals are so moody! One company, 3devo, is founded around the goal of assisting “the transition…to a more sustainable business model – not only from an economic perspective by also in an environmental-friendly practice to 3D printing.” They are doing this by developing an end-to-end solution to shred and extrude filaments for 3D printing. Imagine your corporate water bottle habit could turn your production line into a miniature solid waste authority (you supply the coveralls)

From the country that said, “NOT TODAY!” to coastal flooding

As reported by 3dnatives, Professor Mogens Hinge of the University of Aarhus in Denmark is working in concert with Denmark’s largest plastic recycling company, Aage Vestergaard Larsen A/S, to standardize 3D Printing filament made from recycled plastic waste. The reasons for the joint project are clear – they want to be first to market with a 100% recycled product, ensure uniform quality and be the first Danish filament producer.

From the people that brought you Tang, artificial limbs and remote-controlled ovens

Looking even further afield, but still in our Florida backyard, “NASA is testing a 3D printing program that reuses the plastic already onboard the International Space Station. Objects like packaging. As reported by FedTech, “…astronauts are testing only the bonding properties of the recycled material”, but the ultimate goal is to avoid bringing stock onto the ISS and future missions, like the Artemis, with an eye to utilizing regolith (more commonly known as moondust). Moondust!? What will they think of next?

Summary

Ok – so back to the question at the top – is 3D printing really “green manufacturing”? It’s a real yes, no, maybe, and soon!

With the advent of a new technology, the entire industry has to play catch-up on how to make it the most sustainable version it can be. Based on the recent articles shared here, you get the sense that there are enough folks, distributed across the literal universe, who can make this a reality.

Give us a shout in the comments if you’re thinking about, wishing about, or doing any of the above in your 3D printing world…