Jan 23, 2023

Predictions for 2023: Advanced Manufacturing Poised for Explosive Growth

3DChimera helps companies select and implement advanced manufacturing technologies, including 3D printing, 3D scanning and 3D CAD. As we enter 2023, all the supply chain & logistics challenges that began with the start of the pandemic continue to plague just about every manufacturing business operating in the US. Fortunately, advanced manufacturing can give companies a creative and cost-effective method to take back control of their manufacturing.

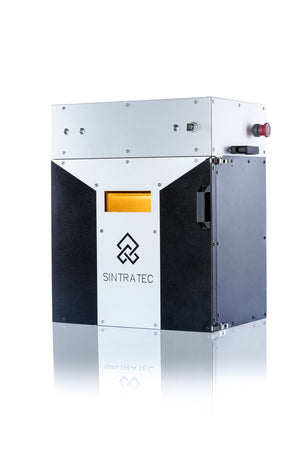

In 2022, we saw a sharp shift in the focus of our customers – from prototypes to manufacturing. The latest advances in powder bed fusion and resin-based 3d printing technologies have poised additive manufacturing as a legitimate technique to reduce risk, provide agility and speed products to market – especially when compared with traditional outsourced manufacturing overseas. Across every industry, we are seeing companies who are ready to expand their manufacturing capabilities into industrial production with additive manufacturing. We predict exponential growth in the number of companies who will utilize additive manufacturing to produce end-use parts in 2023.

Of course, with the economic realities on the horizon, it may be difficult for some companies to make the capital equipment investments required to completely retool their production technology in-house. And this is where our next prediction lies – we expect to see a significant growth in localized 3D printing, 3D scanning and 3D design services. We already see the signs in our business, and we are planning for a steady growth in services through 2023. Localized manufacturing with advanced manufacturing specialists will help many companies to find expert partners, based in the USA, to help kickstart production using these new technologies.

We are also predicting that companies who already have advanced manufacturing technology in-house are going to make investments to maximize the ROI on their current equipment. We expect to see this manifest itself with training, maintenance and automated post-production tools. With specialized training, companies can quickly get guidance on how to get the greatest value out of their equipment with a very minimal investment. It is not unusual to see a 200%+ increase in productivity with minor tweaks to current processes and equipment. And with that increased demand on equipment, we are forecasting that companies are going to get caught up on that maintenance which has been on the back burner for the last few years, in order to squeeze out every bit of value from their tools. And, with the increased productivity on high performing equipment, lights-out manufacturing will become a reality for many, paving the way for additional investments in post processing tools that will help to automate the final finishing steps to make large volumes of parts produced with additive manufacturing ready for the mass market.

From 3DChimera’s perspective, 2023 may be the best year to date to be in the advanced manufacturing business and we are excited to see what unexpected twists and turns are around the corner!

About the Author:

|

Alex is a Co-Founder & CEO @ 3DChimera, a Miami-based supplier of Advanced Manufacturing Equipment including 3D printers, 3D scanners and 3d software. Alex’s company, 3DChimera, was selected as one of the Top 10 3D Printing Service and Consulting companies in the USA by Manufacturing Technology Insights in 2019 & 2020. 3DChimera has helped organizations around the US to select and utilize Advanced Manufacturing Equipment across many different industries having worked with 1000+ Businesses and 100+ Universities since its inception in 2013. Notable clients include Adidas, Bosch, Toshiba, MIT, Sandia National Laboratory, Hewlett Packard, the US Army, Boeing and the Harvard Design School. |