Jan 07, 2024

Additive Manufacturing in 2024 - Predicting a Course Through Market Correction to Innovation

For anyone that follows the stock market closely, the Additive Manufacturing Industry has been top of mind…but not for the reasons that the rest of us might have guessed based on the headlines of years past. By the end of 2023, virtually every publicly traded company in the additive manufacturing industry was significantly down, with some of the major players facing difficult decisions on what the future may hold. The root cause of these declines has been varied and unclear, ranging from a general market slowdown in capital equipment purchases to the consequences of overly aggressive market forecasts and overvaluations. In 2024, we predict a major market correction with a consolidation of several large players in the industry, and more than one of the publicly traded companies shutting their doors for good.

While this prediction may seem dire, rest assured, the additive manufacturing industry is not going anywhere. In fact, while growth has slowed in the stock market, many of the smaller players in the industry are thriving. New entrants to the market, with disruptive price points and capabilities, are expanding the promise of additive manufacturing to more companies than ever before. Additive manufacturing tools are no longer only for huge companies with giant budgets. At the end of 2023, 3DChimera saw a huge surge of business from small and medium sized companies looking to add equipment and capabilities, taking advantage of a short window of opportunity where their competitors took pause due to corporate budget freezes. We predict these trends will continue into 2024, and that the smaller businesses adopting additive manufacturing will begin to lead in their respective markets by unleashing the potential of this transformative technology. Additive manufacturing is a perfect tool for our time, allowing companies to leverage technology to accomplish more with less investment and fixed costs than has been required in years past.

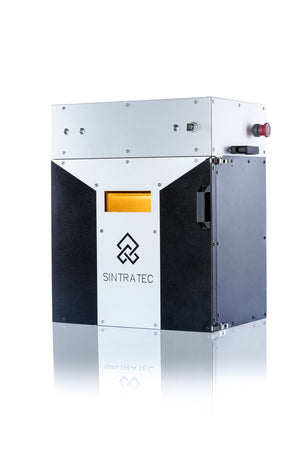

Generally, we have seen a trend towards production applications rather than the traditional 3d printing application of rapid prototyping. With the availability of affordable powder bed fusion printers and high-resolution filament-based printers paired with new finishing techniques, parts can be produced that rival traditional manufacturing in both function and appearance. In fact, we predict that most folks reading this article will purchase an item this year that has been produced with additive manufacturing…and they will have no idea that it was even printed! Our customers at 3DChimera are already producing parts that are sold in major retail environments including the big box stores and online shops that we all love to frequent. Parts are being produced in virtually every industry from toys and sports equipment to automotive and aerospace….and we have only begun to scratch the surface of what can be done with this technology.

Looking ahead, there will be a few shockwaves in the headlines about the additive manufacturing industry in 2024, but the additive manufacturing industry will continue to quietly innovate and find disruptive (and profitable!) applications.

About the Author:

|

Alex is a Co-Founder & CEO @ 3DChimera, a Miami-based supplier of Advanced Manufacturing Equipment including 3D printers, 3D scanners and 3d software. Alex’s company, 3DChimera, was selected as one of the Top 10 3D Printing Service and Consulting companies in the USA by Manufacturing Technology Insights in 2019 & 2020. 3DChimera has helped organizations around the US to select and utilize Advanced Manufacturing Equipment across many different industries having worked with 1000+ Businesses and 100+ Universities since its inception in 2013. Notable clients include Adidas, Bosch, Toshiba, MIT, Sandia National Laboratory, Hewlett Packard, the US Army, Boeing and the Harvard Design School. |