Discover new possibilities with additive manufacturing of injection molding silicone

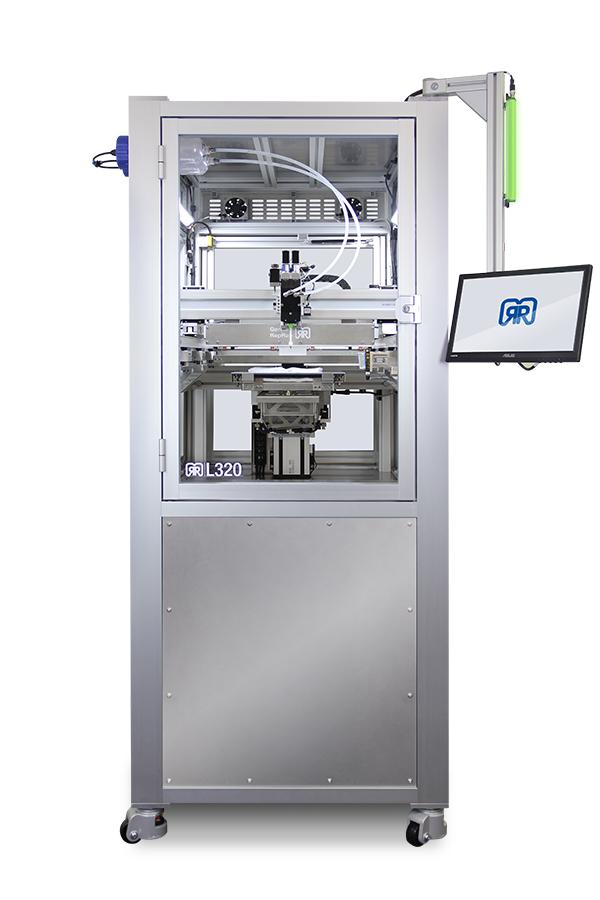

The LiQ 320 3D printer from the Liquid Additive Manufacturing (LAM) series by innovatiQ is a real Game Changer. For the first time it is possible to 3D print with injection molding silicone.

Liquid Silicone Rubber (LSR)

The highly viscous Liquid Silicone Rubber (LSR) is already used in many companies for a wide variety of products and gives confidence in the future use of this 3D LSR material. Users benefit from a shorter time-to-market because insights from the prototype model can be transferred directly to injection molding.

Features

Print Head Technology

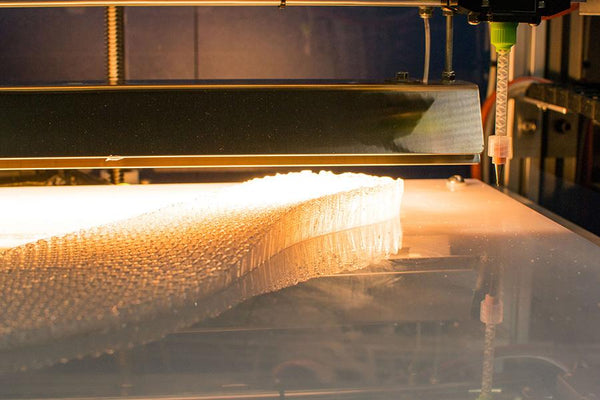

The new printhead technology enables precise metering and mixing ratios. Where conventional production processes such as injection molding require all molecules to be aligned, LAM technology can influence the application direction and thus the cross-linking at the molecular level.

Thermal Cross-linking

A high-temperature halogen lamp releases activation energy to accelerate complete crosslinking, at the molecular level. This fine-tuned reaction, in both small and large objects, is ensured by the driving speed of the lamp. Due to this thermal cross-linking, the printing time is considerably reduced, at the same time the printing result, especially also in terms of time savings, sets new standards.

Safety

The sound safety technology monitors the curing process. The mechanics of the system and program run independent. Deviations are registered and displayed by the system. In the case of irregularities, the print job is automatically stopped. In addition, according to industry standards, the machine is accessible at any time via two doors.

Precision in Continuous Operation

The basic construction of the LiQ 320 / L320 is very stable. The production takes place in Germany with high-quality components. This makes theLiQ 320 / L320 a long-lasting device that has been designed from the outset for commercial use.

Stand-Alone Printing

The touchscreen allows intuitive operation of the printer. This allows each print job to be started comfortably. Optionally, a network connection via Ethernet and WLAN with browser-based control and monitoring via webcam is possible.

Specs

| Build Platform (X/Y/Z) | 250 x 320 x 150 mm 9.8 x 12.6 x 5.9 in |

| Accuracy | +/- 0.2 mm |

| Resolution (Z Layer Height) | 0.22 - 0.9 mm |

| Nozzle Sizes | 0.23 mm 0.4 mm 0.8 mm |

| Minimum Gap Between Layers | 0.1 mm |

| Material | DOW SILASTIC™ 3D 3335 Liquid Silicone Rubber (LSR) |

| Temp Range for 3335 | -60 ° to 200°C |

| Durometer for 3335 | 50A |

| Tensile Strength for 3335 | 8.3 MPa |

| Elongation for 3335 | 525% |

| Tear Strength for 3335 | 50.8 kN/m |

| Compression Set for 3335 | 25% @ 150°C for 70hrs |

| Volume Resistivity for 3335 | 1 x 1016 (Insulating) |

| Other Properties of 3335 | Hydrophobicity (water resistance) Ozone & UV Resistance High Clarity (water clear) |

| Software | Simplify3D (included) |

| Operating Voltage | 230 VAC 110V transformer available |

| File Transfer | USB or Ethernet |

| Display | 15.6" Touch Display |

| Outer Dimensions | 800 x 960 x 1957 mm (fits standard doorway) |

| Weight | Approx 350 kg |

| Technology | LAM (Liquid Additive Manufacturing) |

Media

Learn More: