Oct 23, 2019

Thinking Outside the Box

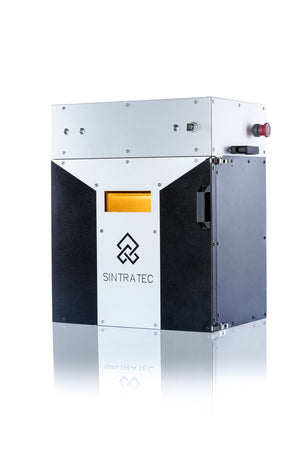

Many people look at the Sintratec Kit and believe the build volume is too small for their application. It’s true that the recommended 90 x 90 x 110 mm build volume would be too small to print many kinds of tall parts. However, there are still ways to print large parts on the Sintratec Kit!

One method is to divide your part into pieces that can fit within the Sintratec Kit's build volume parameters and assemble them afterwards. Doing this, you can get the strength and detail of SLS printed parts, in a size that fits your needs.

We designed a sample block to showcase the different methods of assembling large parts. This block has it all: roll pins, dowel pins, interlocking features, and bolts.

You can fix parts together for a permanent bond by pressing roll pins (sometimes called spring pins) or dowel pins into holes in the two halves. These pins come in convenient sizes and lengths to suit all sorts of geometries. Our sample block shows 1-inch pins of 1/4, 3/16, 1/8, and 1/16-inch diameters. Dowel holes should be a few thousands of an inch undersized to get a proper force-fit. Dowel pins are stronger than roll pins for shear loads, but roll pins are cheaper and can fit in a larger tolerance band. Consider that when choosing the kind of dowels that fit your application best.

You can also design interlocking features that rely on a two-part epoxy to form a strong permanent bond. These can be keyways, locking arms, snap fits, and press-fit features. Our block shows male and female press-fit features printed into the part.

If you wanted to mate two pieces together in a less permanent fashion, you can bolt them together. While you can thread directly into the nylon, we recommend using heat-seated brass inserts. These can be pressed in with a hot iron to provide strong, smooth threads into your part. They are available for most standard sizes. If your part can accommodate a through hole in both halves, you can use a clevis pin, cotter pin, or a quick release pull pin for a different non-permanent solution.

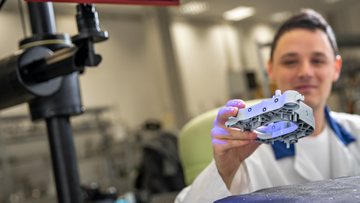

A great example of a part that is too big to fit in the Sintratec Kit’s build volume is this door handle. The door handle is 208 mm long, too large for the Sintratec Kit to be printed as one piece no matter its orientation in the build chamber. This door handle was cleverly split in half to make two pieces about 104 mm long each. 3 holes were cut into either side to press-fit 1/16-inch diameter roll-pins for assembly. These halves were printed in the Sintratec Kit vertically, and there was enough room to print 2 whole door handles.

When assembled, the whole component was both tough and durable, without adding too much weight or cost.